CUSTOM SIZES

2 to 3 week Turn Around

FFKM Molded Seals by M‑Cor

We proudly expand our product line with the latest Perfluoroelastomer (FFKM) O‑rings, custom and extruded tubing.. By combining our engineering expertise with advanced material solutions, we ensure these O‑rings meet the stringent requirements of various industries. As a result, they offer exceptional chemical resistance, reliable thermal stability, and robust mechanical properties.

M‑Cor Inc Recommends These Alternatives to Overpriced FFKM products which are readily available.

Tecnoflon® PFR 95HT Perfluoroelastomer (FFKM) – Fluorine Content: 72%

FFKM Molded seals by M-Cor offer both a broad operational range and high compression set resistance, thanks to its peroxide curing system. Consequently, it withstands chemicals, acids, caustics, ketones, aldehydes, esters, ethers, methanol, solvents, sour gases, hydrocarbons, steam, and hot water.

Furthermore, it performs well in applications from –10 °C to 300 °C. Not only does it support elastomeric sealing elements like O‑rings and gaskets, but it also holds FDA registration for food contact, making it suitable for food processing equipment.

Additionally, we offer this material as raw polymer in 1 kg and 5 kg boxes. To ensure safety, users should avoid skin and eye contact as well as inhaling fumes. Finally, it blends seamlessly with fluoroelastomer compounding ingredients using two-roll mills or internal mixers

.

Tecnoflon® PFR 95 Perfluoroelastomer (FFKM) – Fluorine Content: 72%

Solvay developed this material specifically for aggressive media sealing while also ensuring superior compression set values. Compared to other materials, it performs reliably from –10 °C to 230 °C. In addition, it offers robust resistance to hot organic and inorganic acids, caustics, ketones, aldehydes, esters, ethers, alcohols, fuels, solvents, sour gases, hydrocarbons, steam, hot water, ethylene and propylene oxide, mixed process streams, potent active pharmaceutical ingredients (APIs), and aggressive cleaning agents.

As a result, this formulation excels in steam‑in‑place (SIP) and clean‑in‑place (CIP) procedures. Moreover, it supports the manufacturing of elastomeric sealing elements such as O‑rings and gaskets. Like PFR 95HT, it is FDA-registered for food contact applications, ensuring suitability for food processing equipment.

To meet various industry needs, we provide this material in 1 kg and 5 kg boxes. As with all fluoroelastomers, users should follow safety guidelines to prevent skin or eye contact and inhalation of fumes. Furthermore, it mixes easily with the cure system and other typical compounding ingredients using two-roll mills or internal mixers.

Common Applications for Tecnoflon® PFR 95HT

An excellent choice for sealing elements—O‑rings and gaskets—used in the chemical, petrochemical, food processing, pharmaceutical, aerospace, and semiconductor industries. Due to their exceptional properties, they help maintain efficiency and reliability in critical applications.

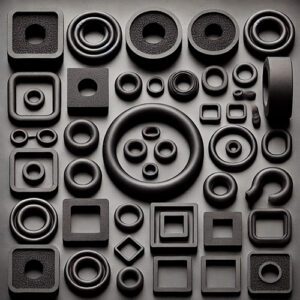

FFKM SAMPLE DESIGNS

Food Processing Applications

95 HT materials hold FDA food contact registration, they are well-suited for food processing equipment. In particular, they handle various food types, including non‑acid and acid aqueous products, dairy products, low‑moisture fats and oils, beverages, and bakery items. To comply with industry regulations, we follow strict compounding guidelines that limit specific curatives, fillers, and process aids.

Fluid Resistance

Our products demonstrate outstanding resistance to inorganic and organic acids, alkalis, water/steam, ketones, esters, ethers, aldehydes, alcohols, hydrocarbons, and sour gas. Because of this, volume swelling remains below 10%.

However, we do not recommend their use in highly fluorinated fluids, as performance may be compromised.

Properties

Excellent Chemical and Thermal Resistance

Our FFKM O‑rings withstand exposure to more than 1,800 chemicals. Because of this, they serve as an ideal solution for chemical processing, semiconductor fabrication, and pharmaceutical manufacturing.

Equally important, they sustain reliable performance at temperatures up to 327 °C, making them a top choice for aerospace applications.

Enhanced Performance and Durability

The fully fluorinated structure of our FFKM Molded Seal by M-Cor provides not only exceptional chemical and thermal resistance but also outstanding mechanical strength. As a result, they exhibit remarkable resistance to compression set and maintain seal integrity under fluctuating pressures and temperatures.

Diverse Industrial Applications

Given their superior durability, our FFKM Molded Seals by M-Cor excel in a wide range of industries, including:

- Aerospace: Ensuring resilience in extreme temperatures and aggressive chemical environments.

- Oil and Gas: Withstanding high temperatures and harsh chemicals.

- Semiconductor Manufacturing: Offering high chemical resistance for precision applications.

- Pharmaceuticals and Biotechnology: Providing chemical inertness for sensitive processes.

- Chemical Processing: Delivering long-lasting sealing solutions for aggressive chemicals and high temperatures

Our Commitment to Quality

We dedicate ourselves to manufacturing excellence. By maintaining the highest quality standards, we ensure our FFKM O‑rings enhance operational efficiency, reduce maintenance requirements, and maximize uptime.

For businesses seeking reliable sealing solutions, our O‑rings offer long-term performance and durability. To learn more, please contact us.

| Property | Kalrez® 4079 | Kalrez® 6375 | Tecnoflon® PFR 94 | Tecnoflon® PFR 95HT |

|---|---|---|---|---|

| Hardness (Shore A) | 75 | 75 | 71 | 72 |

| Tensile Strength (MPa) | 16.88 | 15.16 | 20.0 | 18 |

| Elongation at Break (%) | 150 | 160 | 155 | 200 |

| Compression Set (%) | 25 (70h @ 204°C) | 30 (70h @ 204°C) | 18 (70h 204°C) | 19 (70h @ 204°C) |

| Max Service Temp (°C) | 316 | 275 |

235

|

Over 300 |

| Chemical Resistance | Excellent resistance to organic acids, inorganic acids, and aldehydes. Not recommended for hot water/steam or certain amines. | Broad chemical resistance, suitable for acids, bases, amines, steam, ethylene oxide, and many aggressive chemicals. | Exceptional resistance to nearly every chemical class. | Exceptional resistance to nearly every chemical class; outperforms triazine-curable FFKM at high temperatures under water and steam. |

| Applications | General-purpose use in O-rings, diaphragms, seals, and other parts in the chemical process and aircraft industries. | Designed for the chemical processing industry, suitable for a wide range of chemicals and temperatures. | General-purpose applications requiring high chemical resistance. | Applications requiring high chemical and heat resistance, especially under water and steam conditions. |

| Manufacturer | DuPont | DuPont | Solvay | Solvay |

Note: Compound Fluorine content 72%